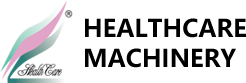

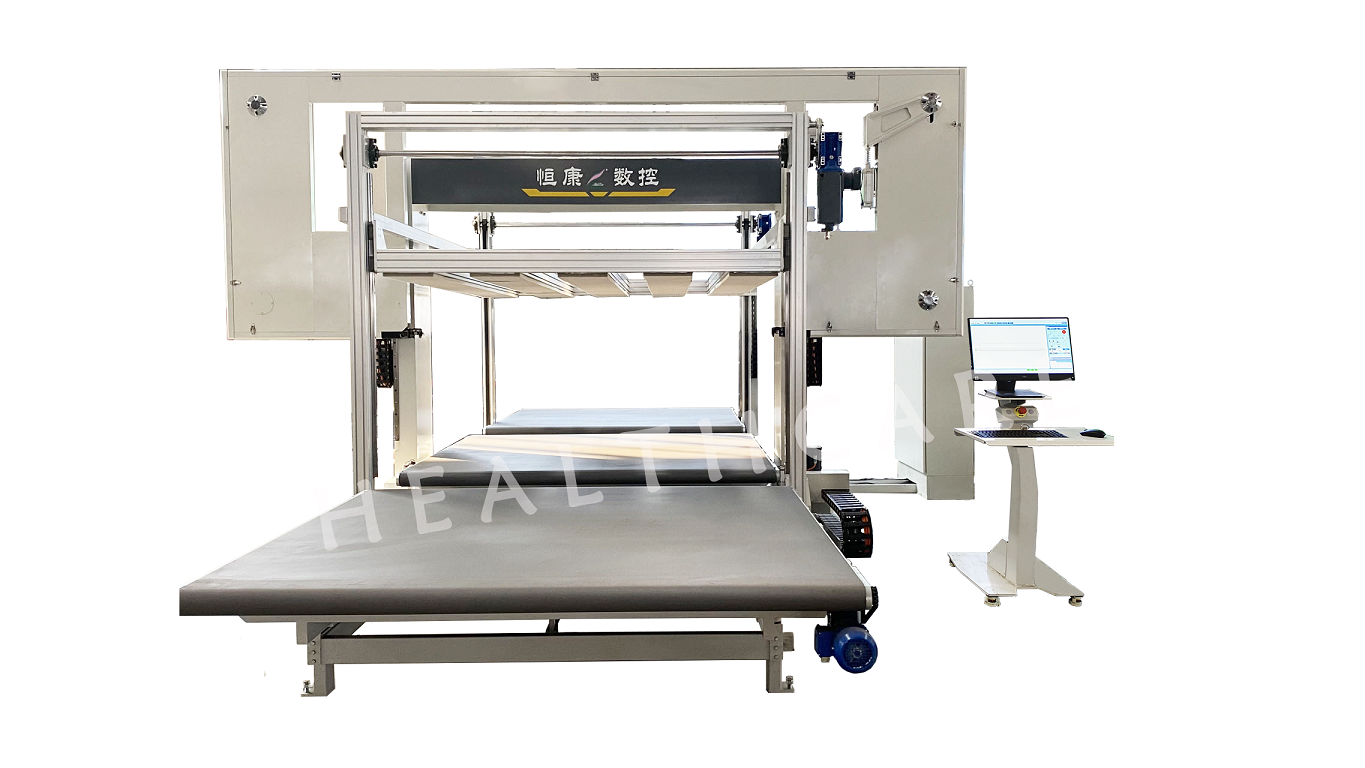

CNCHK-9.1 Vertical Continuous Blade Foam Cutting Machine

CNC Foam Cutting Machine with High Efficiency

CNCHK-9.1 is continuous blade cutting machine, the most advantage of the foam cutting machine is the fast speed. The CNC foam cutting machine adopts absolute value of system, stable and reliable. Thanks to the high level of automation, including automatic foam feeding and automatic knife adjustment, resulting in various advantages for foam fabrication including improved dimensional accuracy, increased cutting speed, consistency of contoured parts, reduced foam dust.

The foam cutting machine equipped with grinding device and knife guide, also improves the accuracy, using toothed-knife or smooth knife for cutting different materials.

The foam cutting machine can do both contour cutting and trimming for foam blocks or sheets.

Usually the foam cutting machine works with lifting tables for loading and unloading, to shorten the downtime and save man-power. This foam cutting machine can be easily integrated to an automatic cutting line, by adding horizontal slicing machine and Vacuum device or other Healthcare CNC foam cutting machines, which significantly improves working efficiency.

It’s good at cutting foam, coated material (such as foam with fabric), fiber etc. The foam cutting machine is very good solution for the foam, mattress, furniture production, and also packing industry, especially for processing large quantities.

Technical Data

|

Max. Block size |

3000*2300mm |

|

Max. Block Height |

1000mm, 1200mm |

|

Blade size |

14770*3.5*0.6mm, 15150*3.5*0.6mm |

|

Speed |

Max. 60m/min |

|

Accuracy |

±1mm |

|

Torsion range of blade |

±360° |

|

Grinding device |

Installed |

|

Option |

Press roller, Baffle, Lifting table |

Advantage

● Fast cutting speed.

● Simple operation with state-of-the art control technology.

● High level of automation: automatic foam feeding, automatic knife adjustment, etc.

● Can continue the cutting after break.

● Absolute value of system, stable and reliable.

● Few wear parts.

● Reduce manpower.

● Dust-free.

● Can be upgraded to an automatic cutting line.

Applications

● Foam fabrication

● Upholstered furniture

● Mattress

● Packaging

● Automotive

● Household

Materials

● Flexible PU foam

● PE

● Polyester fiber

● Coated material (such as foam with fabric)

● Rebond foam

Standard

● Knife guide improves the cutting accuracy.

● ZWCAD (available with commonly used keyboard shortcuts, automatic typesetting, one button for creating cutting path)

● Electric cables with superior resistance to bending and twisting

● With automatically sharpening device, it can also improve the cutting accuracy.

● Lower knife twisting device designed with blowing function for cleaning and cooling the band knife

Options

● Baffle (manual or automatic)

● Press roller

● Lifting table for loading and unloading

● Extension table

● Nesting software

● Can upgrade to cutting line by adding horizontal slicing machine.

Samples

Factory Show